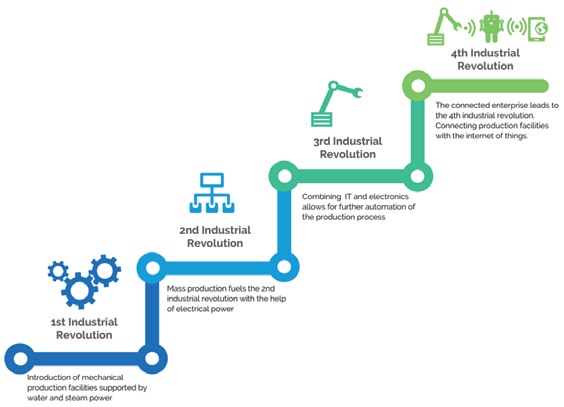

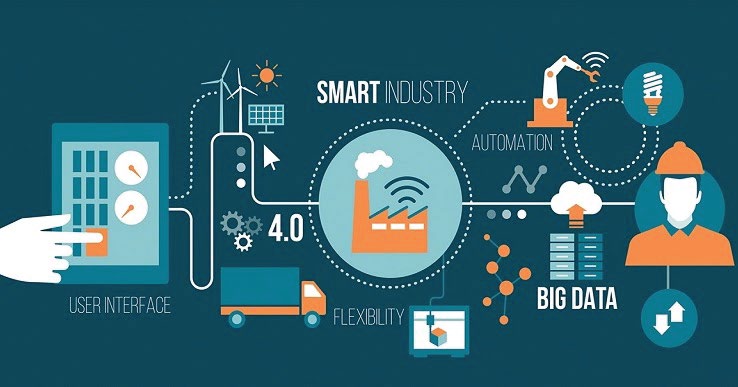

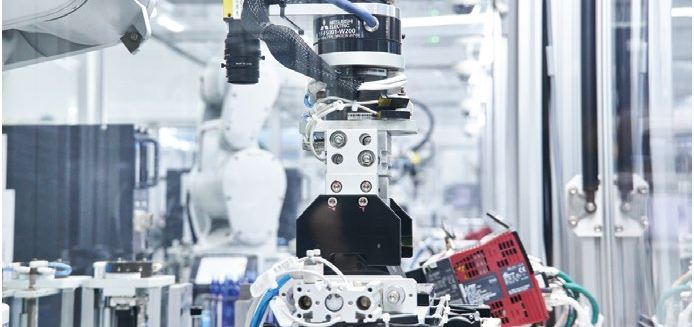

Welcome to the realm of manufacturing digital transformation! In the face of unpredictable changes in the global market, the manufacturing industry requires continuous adaptation. To overcome these challenges, it's crucial to secure global competitiveness and develop individual response capabilities. Manufacturing digital innovation goes beyond just implementing new technologies; it involves reevaluating and optimizing the entire manufacturing value chain, from design and development to production, logistics, sales, and post-service. Digital innovation must transcend individual manufacturing units and focus on enhancing value chain competitiveness. One of the most significant technological advancements in recent years is the integration of artificial intelligence (AI) into manufacturing. AI enables predictive maintenance and real-time monitoring of production processes, helping to identify and prevent potential issues before they occur. Furthermore, intelligent automation and advanced analytics support improved decision-making and increased efficiency. Another exciting development in manufacturing technology is the emergence of digital twin technology. Digital twins, which are virtual replicas of physical assets, processes, or systems, allow for virtual simulation and optimization of manufacturing processes. This leads to enhanced performance, reduced downtime, and overall efficiency improvements. Additionally, digital twins facilitate virtual testing and validation of designs, enhancing the design and development processes. Next-generation communication technologies such as 5G and IoT are also revolutionizing data collection and transmission within manufacturing operations. These technologies enable real-time data transfer, remote control, advanced tracking, and monitoring systems, facilitating more accurate and efficient decision-making and enhancing overall performance and productivity. By integrating these technologies across the entire value chain, companies can optimize processes, reduce costs, and increase customer satisfaction. We encourage all companies, regardless of size or industry, to embark on this digital innovation journey. With the right tools and strategies, companies can maintain competitiveness and thrive in today's rapidly changing digital environment.

- Path to Smart Factory

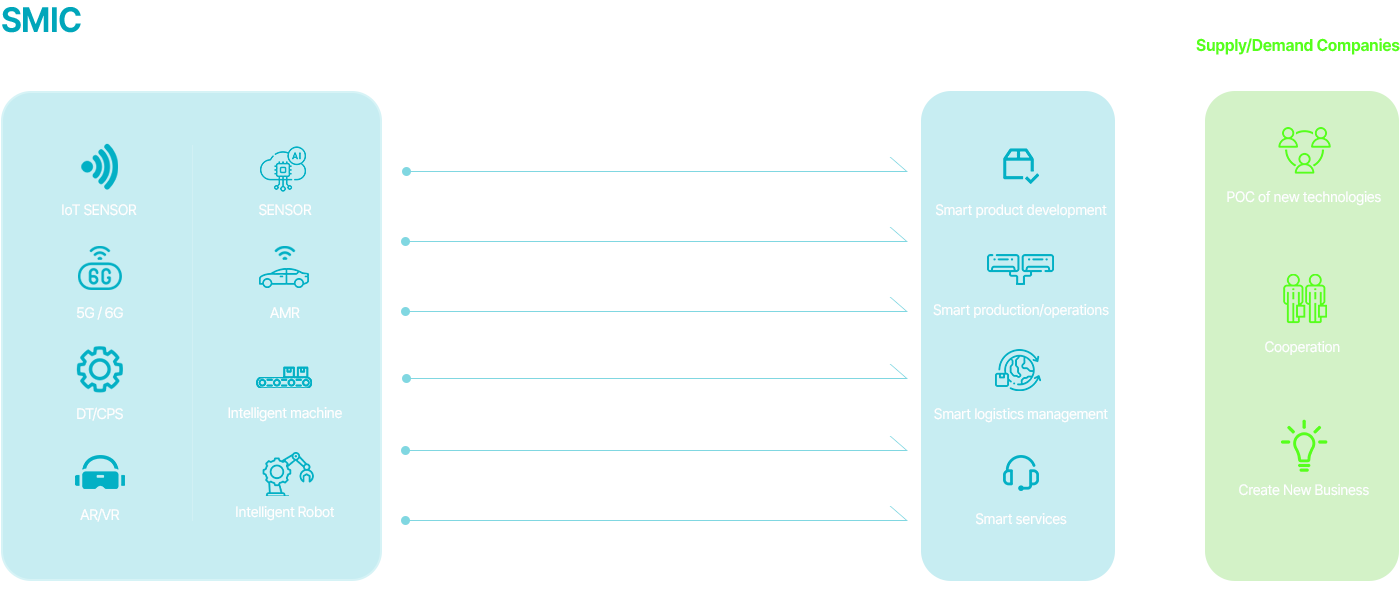

- Missions of SMIC

- R&D and POC

- AI Manufacturing Services

- Industry Value Chain Data infrastructure

- Industrial standard certification

- DX Training

- DX Network

- DX Consulting

R&D and POC

-

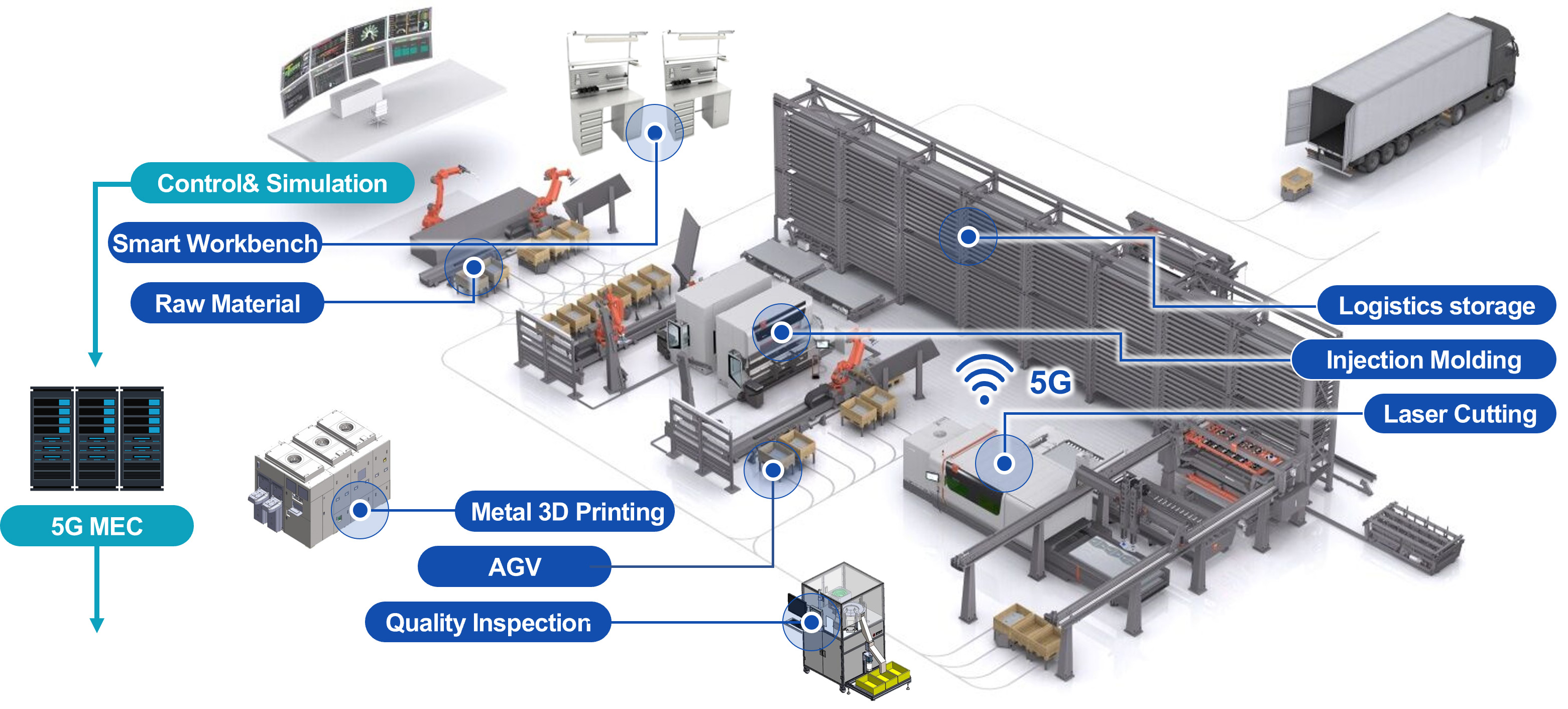

- Modular Process Automation Testbed

-

Digital Manufacturing Process Testbed based on Interoperability

- IT-OT Integrated Data Management

-

- Data Center for AI Analysis and Manufacturing Data Storage

- Network Integration based on 5G and TSN (Time Sensitive Network)

-

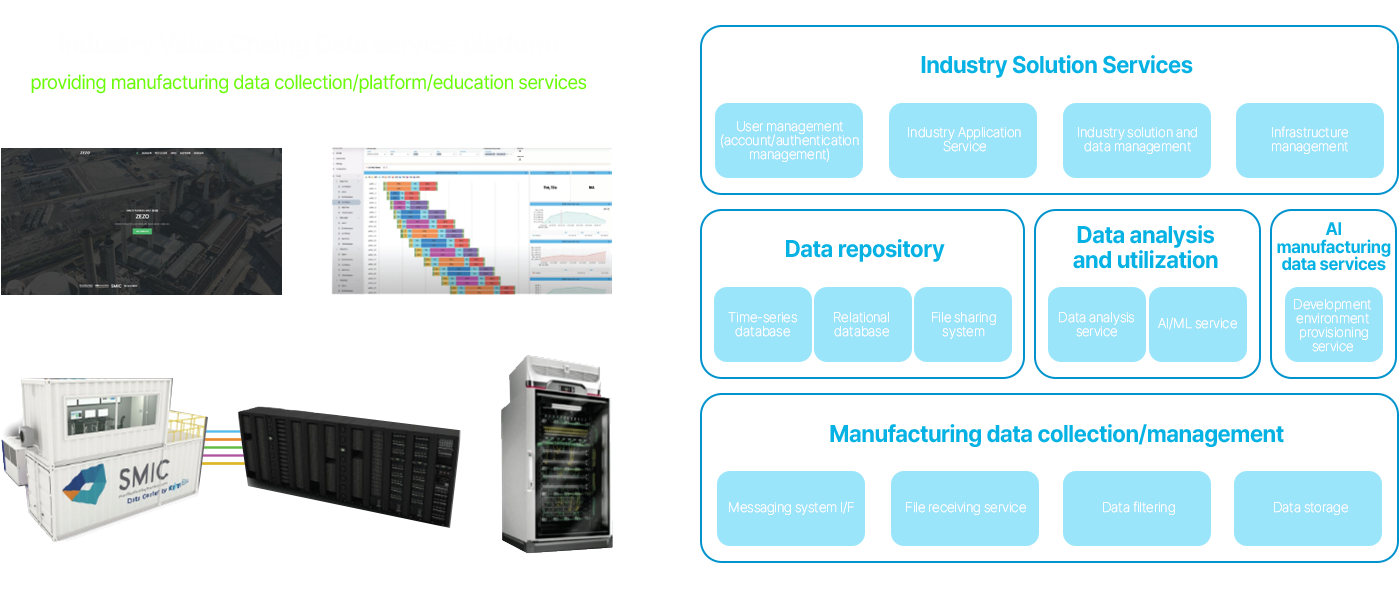

Manufacturing Data Collection and AI/Big Data Analysis Service

through the ZEZO platform

-

- Key Demonstration Technology

- AI-based Product Inspection

- Interactive Control System

- Industrial 5G

- Digital Twin Products

- High-capacity, High-speed Process Data Analysis

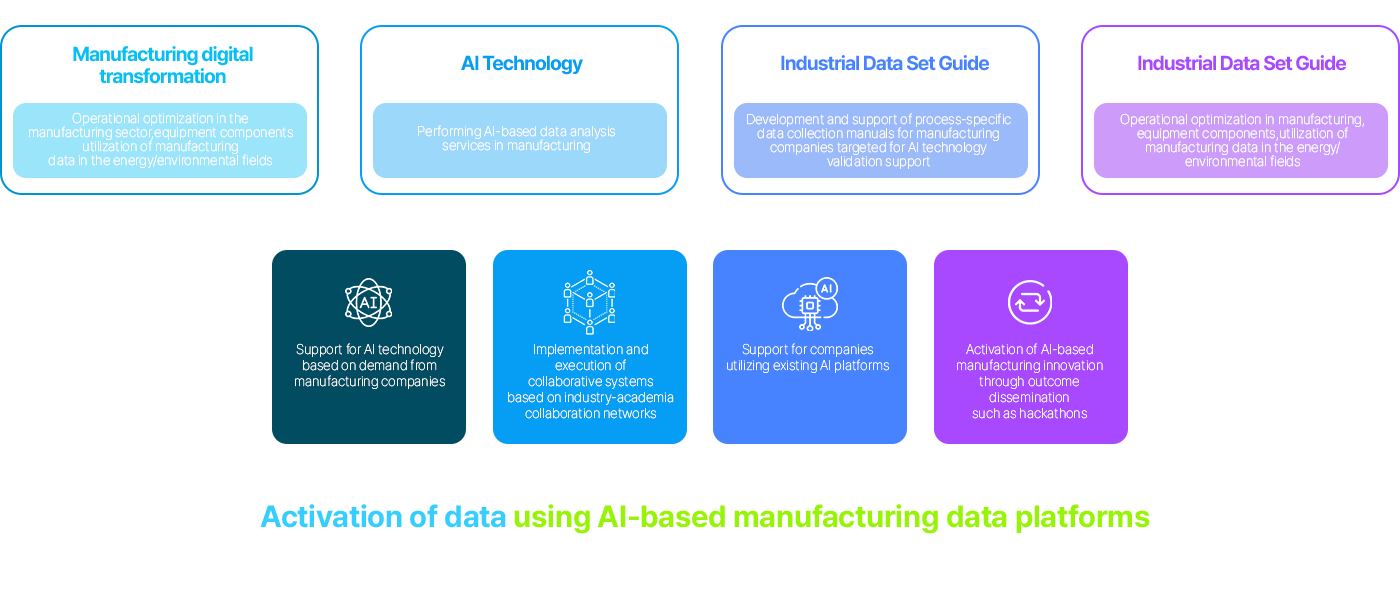

AI Manufacturing Services

Industry Value Chain Data infrastructure

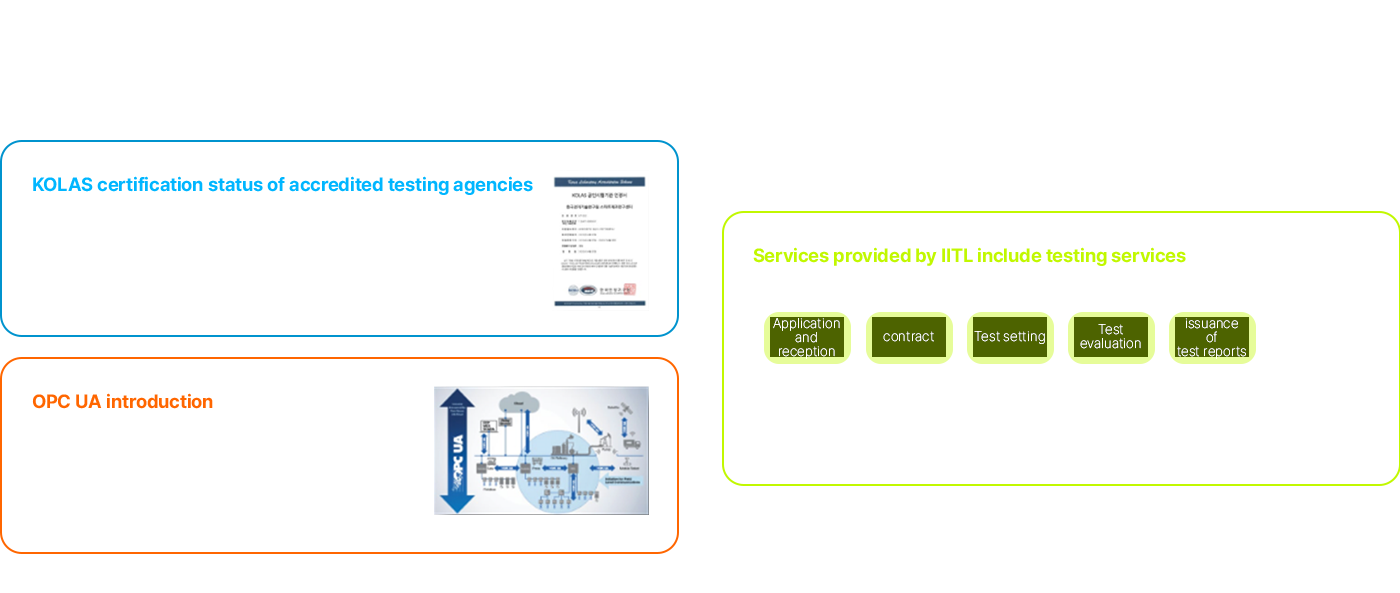

Industrial standard certification

DX Training

DX Network

DX Consulting

- Membership

- Sponsor

Location

- Address 705, Haean-ro, Sangnok-gu, Ansan-si, Gyeonggi-do

- TEL +82-31-498-7161